An Overview of LNG: Production, Power, and Pond’s Expertise

Author:

Patrick Shannon, PE | Technical Director, Mechanical Engineering | [email protected]

Introduction

Natural gas is a fossil energy source primarily composed of methane. It’s typically transported in its gaseous state via pipeline and serves as a primary energy source used for heating and generating electricity. The United States is the world’s leading natural gas producer, representing nearly a quarter of global production. To meet the growing need for natural gas in the international market, producers have turned to the use of natural gas in its liquefied form.

LNG Basics

Liquefied natural gas, or LNG, is a natural gas that has been cooled to a liquid state (about -260 degrees Fahrenheit) for transport and storage. The volume of gas in this liquid form is about 600 times smaller than its gaseous state, making it much easier to be transported. This enables international markets that are far from producing regions to still have access to natural gas.

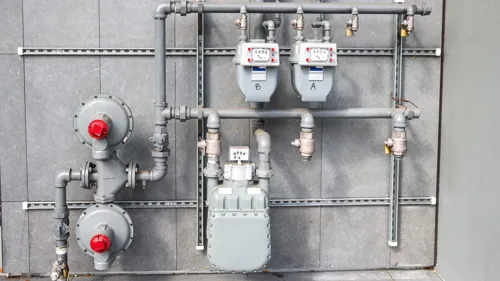

Liquefying natural gas is one way to transport natural gas long distances where pipelines aren’t feasible. In its condensed form, LNG is shipped in special storage tanks to terminals all around the world. At these terminals, the LNG is returned to its gaseous state where it can be transported by pipeline to power plants, industrial consumers, and distribution companies.

LNG Usage

For large-volume ocean transport, LNG ships are equipped with sophisticated leak detection, advanced radar systems, and numerous other technologies to ensure safe transportation. Once the ship enters the receiving port, LNG is off-loaded into storage tanks and later regasified for transport via distribution pipeline networks.

LNG is also transported in smaller quantities, usually by truck or shorter ocean distances. Power plants use a technique called peak shaving to level out energy consumption by storing LNG during months of low usage. During peak demand, customers can tap into the LNG supply to maximize the performance of their energy grids.

Pond’s LNG Capabilities

Pond has the expertise to seamlessly guide clients through the intricate process of bringing LNG projects to life. From initial concept to final execution, we are committed to delivering tailored solutions that exceed expectations and drive success. Our team of seasoned LNG engineers and designers are experts in NFPA 59A site evaluations, FEED studies, and detailed design for LNG peak shaving and marine loading projects. Our LNG expertise extends to pre-treatment and liquefication facilities, loading and unloading stations, and plant modifications and upgrades. We deliver top-tier expertise at every phase of the project lifecycle, whether it’s facility layout, process design, safety compliance, or feasibility studies. Our team is well-versed in local and international standards, ensuring that every design and engineering decision aligns with industry regulations, environmental considerations, and safety protocols, providing our clients with peace of mind throughout the project. Learn more about Pond's oil & gas solutions.