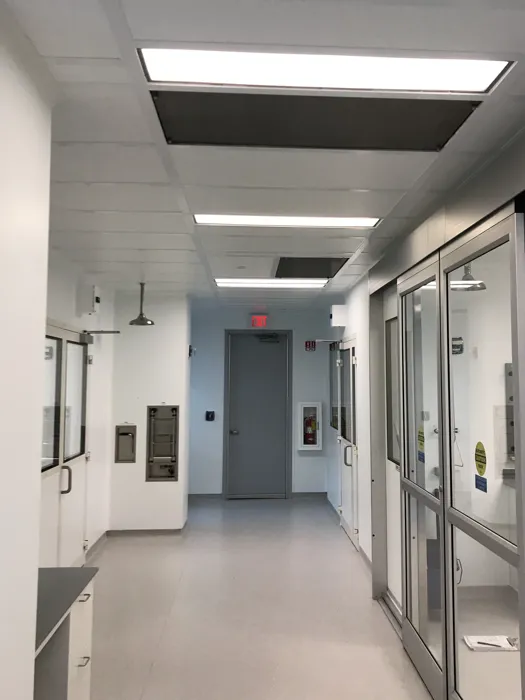

Pharmaceutical Manufacturer Clean Room

Pond’s professionals provided all in-house design services for Vero Biotech’s pharmaceutical manufacturing facility. The project included the renovation of a clean-room suite for this innovative medical technology that produces cassettes of nitric oxide, or NO, for patient inhalation use in a hospital setting and beyond, wherever nitric oxide treatment is needed. Especially critical for hypertensive newborns, this therapeutic agent relaxes vascular smooth muscle cells. Pond’s design services included lab gases, RO water, critical electrical systems, clean wall systems, fan filter units, and mechanical systems for room pressure cascades.

The project featured several key highlights, beginning with developing a comprehensive room pressure cascade plan to ensure optimal airflow management. A thorough utility study was conducted to address the facility’s infrastructure needs, alongside a critical systems study to enhance operational efficiency. The production suite layout was carefully designed to maximize space utilization and workflow optimization. Additionally, implementing a clean wall system contributed to maintaining stringent cleanliness standards. Engineering services were meticulously integrated throughout the project to guarantee seamless functionality. Furthermore, the incorporation of OA HEPA Filtration and Fan Filter Units adhered to both FDA and EU standards, ensuring compliance with regulatory requirements.

The project featured several key highlights, beginning with developing a comprehensive room pressure cascade plan to ensure optimal airflow management. A thorough utility study was conducted to address the facility’s infrastructure needs, alongside a critical systems study to enhance operational efficiency. The production suite layout was carefully designed to maximize space utilization and workflow optimization. Additionally, implementing a clean wall system contributed to maintaining stringent cleanliness standards. Engineering services were meticulously integrated throughout the project to guarantee seamless functionality. Furthermore, the incorporation of OA HEPA Filtration and Fan Filter Units adhered to both FDA and EU standards, ensuring compliance with regulatory requirements.

Project Photos

CLIENT

Vero Biotech

LOCATION

Atlanta, GA

Similar Projects