Understanding NPRM DIMP: Recordkeeping Practices, Presence of Qualified Personnel, District Regulator Stations

Author:

Andy Lawton, PE | Principal - Vice President | [email protected]

In early 2023, the Pipeline and Hazardous Materials Safety Administration (PHMSA) proposed revisions to the pipeline safety regulations for natural gas distribution lines after the 2018 Merrimack Valley incident, which resulted in one fatality. In the following proposed revisions, PHMSA aims to prevent catastrophes specifically caused by the overpressurization of low-pressure distribution systems.

Overview of Proposed Amendments:

- Recordkeeping Practices — § 192.638

- Presence of Qualified Personnel — §§ 192.640 and 192.605

- District Regulator Stations — §§ 192.195 and 192.741

Recordkeeping Practices

Operators are required to keep records about their gas distribution pipelines under 49 CFR part 192. The recordkeeping requirements specific to DIMPs include:

- 1007(a) requires operators to identify reasonably available information necessary to develop an understanding of the characteristics of their pipelines, identify applicable threats, and analyze the risk associated with the threats.

- 1007(a)(3) requires that operators have a plan to collect information needed to conduct the risk analysis required in DIMP.

- 1007(a)(5) requires operators to capture and retain information on any new pipeline installed, including, at a minimum, the location of the pipeline and the material of which it is constructed.

In addition to recordkeeping requirements for DIMP compliance, operators must also consider the data needed to comply with other 49 CFR part 192 requirements, such as corrosion control (§ 192.491) and operator qualification (§ 192.807). Construction records, maps, design and installation records (including protection against overpressurization), and the pipeline’s operating history must be available to ensure O&M procedures remain consistent with federal safety requirements. The Merrimack Valley incident illustrated how incomplete or outdated records can delay response coordination and become catastrophic.

Proposed Addition of 192.638

In a new § 192.638, PHMSA intends to identify any records essential to pressure control. Operators would be required to identify records that document the characteristics of the pipeline, and which are “critical to ensuring proper pressure controls” for the system.

In § 192.638(a), the types of records PHMSA deems critical to ensuring proper pressure control include current location information for regulators, valves, and underground piping; attributes of the regulator(s), such as set points, design capacity, and the valve failure position; the overpressure protection configuration; and other records deemed critical by the operator.

In § 192.638(b), PHMSA proposes to require that if an operator does not yet have traceable, verifiable, and complete records, then the operator must develop a plan for that.

In § 192.638(c), PHMSA proposes that operators must collect records needed to meet this standard on an opportunistic basis, defined as occurring during normal operations conducted on the pipeline including (but not limited to) design, construction, operations, or maintenance activities.

In § 192.638(d), PHMSA proposes that operators ensure the records required in this section are accessible to personnel performing or overseeing design, construction, operations, and maintenance activities.

In § 192.638(e), PHMSA proposes that once a record is generated or collected under this section, operators must keep the record for the life of the pipeline.

In § 192.638(f), PHMSA specifies that the requirements in this section would not apply to master meter systems, liquefied petroleum gas distribution pipeline systems that serve fewer than 100 customers from a single source, or any individual service line directly connected to a transmission, gathering, or production pipeline that is not operated as part of a distribution system.

Presence of Qualified Personnel

Operators are not currently required to monitor gas pressure with qualified personnel or equipment with the ability to shut off the flow of gas. Pipelines are often monitored remotely using SCADA – some of which are not capable of remote or automatic shut-off – and this process can create delays in emergency response.

After the 2018 Merrimack Valley incident, PHMSA was directed to issue regulations requiring qualified personnel to monitor gas pressure at district regulator stations during any construction project that has the potential to cause overpressurization.

Proposed Addition of 192.640

PHMSA proposes an additional layer of safety at district regulator stations during construction projects by requiring qualified personnel to be present, monitor the gas pressure, and have the capability to shut off the flow of gas during an overpressurization event. This provision would not apply if a district regulator station with a remote pressure monitoring system has the capability for remote or automatic shutoff.

In § 192.640(a), PHMSA proposes that operators of a distribution system must evaluate planned and future installation, modification, or replacement of, or upgrade construction projects and identify any potential for an overpressurization to occur at a district regulator station. Operators must perform this evaluation before performing activities that could result in overpressurization.

In § 192.640(b), PHMSA proposes that once the evaluation is complete if an operator has determined that a construction project activity presents a potential for overpressurization, then the operator must ensure that at least one qualified employee or contractor with the capability to shut off the flow of gas is present at that district regulator station to monitor the gas pressure during the construction project activity.

Note: They should also be qualified on the relevant proposed new O&M requirements discussed in subsections IV. D and E.

In § 192.640(c), PHMSA proposes to require that, when monitoring the system as described in this section, the qualified personnel should be provided, at a minimum, information regarding the location of all valves necessary for isolating the pipeline system and pressure control records ( see § 192.638). Further, under paragraph (c), PHMSA proposes that operators must also ensure that qualified employees monitoring the gas pressure have information regarding emergency response procedures.

Overall, the proposals in § 192.640 would reduce the time to respond to an overpressurization by ensuring qualified employees are on-site or at an alternative location, and that they are capable of actively monitoring the gas pressure during certain construction project activities.

Proposed Amendment to 192.605

PHMSA proposes to revise § 192.605 regarding operations, maintenance, and emergencies by adding paragraph (b)(13) to ensure gas distribution operators have procedures for implementing the monitoring requirements in the proposed § 192.640.

District Regulator Stations

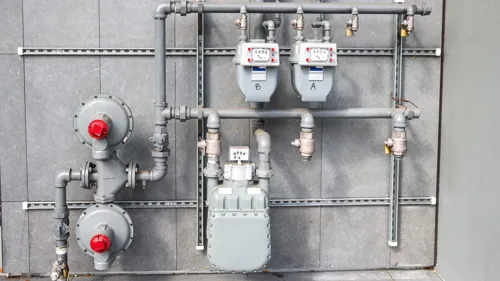

Gas distribution systems are designed to operate at or below MAOP. District regulator stations receive gas from a high-pressure source (such as a transmission line) and adjust the pressure so it can be delivered to a low-pressure system without exceeding its MAOP. The typical approaches to overpressure protection in use today are pressure relief valves, a worker and monitor regulator system, and automatic or remote shutoff (slam-shut) valves.

Section § 192.195 currently defines the minimum requirements for protection against overpressurization stating that pipelines must have pressure-relieving or pressure-limiting devices that meet the design requirements of §§ 192.199 and 192.201. Additionally, sections §§ 192.739 and 192.741 describe the minimum requirements for inspections and telemetering respectively.

The pipeline safety regulations for overpressure protection of low-pressure distribution systems have remained unchanged since their inception in the 1970s. The common overpressure protection methods are safe under normal operating conditions, but they are too easily defeated, as the Merrimack Valley incident has demonstrated.

Proposed Amendment to 192.195

PHMSA has proposed three additional requirements for district regulator systems.

In § 192.195(c)(1), each district regulator station must consist of at least two methods of overpressure protection appropriate for the configuration and location of the station.

In § 192.195(c)(2), each district regulator station that services a low-pressure system must minimize the risk of overpressurization that could be caused by any single that either immediately or over time affects the safe operation of more than one overpressure protection device.

In § 192.195(c)(3), each low-pressure distribution system must have the ability to remotely monitor gas pressure at or near the location of overpressure protection devices.

Of course, these proposed amendments would impact the current telemetering requirements in § 192.741. To account for these changes, PHMSA has proposed a new paragraph (d) to specify that operators of low-pressure distribution systems that are new, replaced, relocated, or otherwise changed must monitor gas pressure under § 192.195(c)(3).

How Pond Can Help

Pond provides full-service consulting for integrity management, risk assessment, pipeline design, and field services for natural gas distribution lines. In compliance with PHMSA and its expanded regulations, our experts work with natural gas operators to mitigate risks and ensure safety for the community, the environment, and nearby infrastructure. Learn more about Pond’s comprehensive regulatory compliance expertise.