Integrity Engineering Services

Pond provided a full suite of design, construction, and pipeline integrity services to Garland Power & Light (GP&L) for their 16-inch natural gas pipeline. The project began with an HCA analysis and integrity management plan (IMP) rewrite.

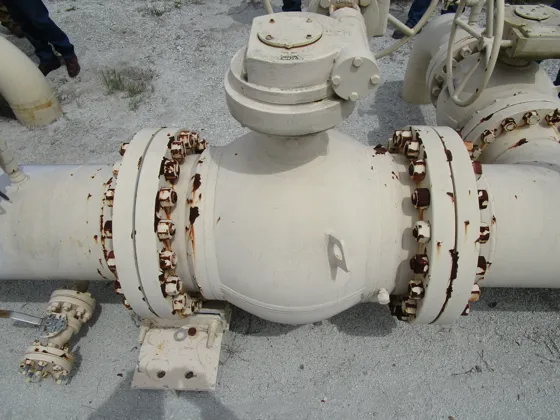

After the IMP was submitted, GP&L asked Pond about ILI services as the compliance date was approaching. A site visit was made to verify piggability of the pipeline. During the site visit, numerous deficiencies were observed. Pond recommended designing and performing the repairs prior to the ILI tool run for safety reasons.

The trap repairs and overpressurization designs were submitted, approved, and executed by Pond. Upon completion of repairs, Pond managed the pipeline cleaning and ILI process. While managing the ILI process, Pond performed an API 570 inspection on vaulted and exposed pipelines, soil-to-air interfaces, and traps.

While the API 570 was conducted, a survey crew from Pond's Pasadena, Texas office performed close interval survey (CIS), and direct current voltage gradient (DCVG) surveys. The CIS and DCVG survey data were overlaid and used in conjunction with the ILI data to determine dig locations for direct assessment. Pond has continued to support GP&L with coating specifications, odorization design, and cathodic protection services.

After the IMP was submitted, GP&L asked Pond about ILI services as the compliance date was approaching. A site visit was made to verify piggability of the pipeline. During the site visit, numerous deficiencies were observed. Pond recommended designing and performing the repairs prior to the ILI tool run for safety reasons.

The trap repairs and overpressurization designs were submitted, approved, and executed by Pond. Upon completion of repairs, Pond managed the pipeline cleaning and ILI process. While managing the ILI process, Pond performed an API 570 inspection on vaulted and exposed pipelines, soil-to-air interfaces, and traps.

While the API 570 was conducted, a survey crew from Pond's Pasadena, Texas office performed close interval survey (CIS), and direct current voltage gradient (DCVG) surveys. The CIS and DCVG survey data were overlaid and used in conjunction with the ILI data to determine dig locations for direct assessment. Pond has continued to support GP&L with coating specifications, odorization design, and cathodic protection services.

Project Photos

CLIENT

Garland Power & Light

LOCATION

Garland, Texas

Markets

Similar Projects